Metal Deck Roll Forming Machine

Send Inquiry

As a seasoned manufacturer of metal deck roll forming machines in China, Beenew specializes in crafting tailored floor deck forming solutions for clients. These machines efficiently produce floor decks vital for steel-framed structures, particularly in prefab constructions, expansive factories, and public facilities.

Beenew Metal Deck Roll Forming Machine Introduction

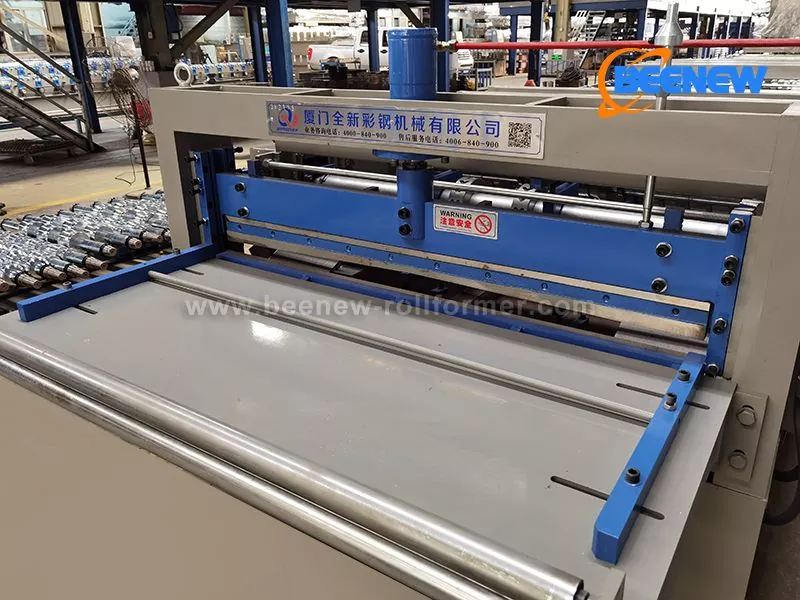

The Metal Deck Roll Forming Machine carefully built by Beenew is based on high-strength steel. Through exquisite welding technology, it maximizes the structural strength, ensuring that the machine can stand firm and operate stably on a long-term, high-intensity production line. The roller is made of GCr15 material, which is known as the "king of bearing steel". This material has excellent hardenability, hardness, wear resistance, contact fatigue durability, dimensional stability and corrosion resistance, which brings unprecedented precision and efficiency to the forming operation, further improving the performance and reliability of the overall production line.

Beenew Metal Deck Roll Forming Machine Parameter

|

Item |

Parameters |

|

Material Thickness |

0.8-1.2mm |

|

Driving Motor |

18.5kw |

|

Forming Station |

23 |

|

Roller Material |

GCr15 |

|

Shaft Diameter |

85mm |

|

Shaft Material |

45# steel |

|

Hydraulic Station Power |

5.5kw |

|

Cutting Length Precision |

±2mm |

|

Control System |

PLC |

|

Machine Dimension |

12902*1700*1700mm |

Beenew Metal Deck Roll Forming Machine Feature and Application

Beenew metal deck roll forming machine is a machine specially designed for producing steel floor decks. It cold-rolls the steel coil raw materials through the machine mold to form the required shape of the floor deck. This type of floor deck is mainly used in steel structure buildings, such as large factories, stadiums, etc.

The floor decking forming machine has high production efficiency and improves the benefits of the enterprise; compared with traditional floor decking, it does not pollute the environment and meets the requirements of modern green buildings; the machine has automated production, and compared with traditional floor decking, the construction speed of steel structure floor decking is faster, which improves the construction speed and saves the construction cost of the construction company.

Beenew Metal Deck Roll Forming Machine Detials

The rollers of the Beenew floor deck forming machine are made of 45# forgings after fine processing and hard chrome plating (bearings are embedded after wave height above 50mm); the shearing blades are made of Cr12 die steel wire cut and heat treated, which are sharp and have high toughness; the shearing adopts hydraulic front shear and rear shear to avoid material waste.

English

English lugha ya Kiswahili

lugha ya Kiswahili  Монгол хэл

Монгол хэл  Español

Español  Português

Português  русский

русский  Français

Français  日本語

日本語  Italiano

Italiano  한국어

한국어  Malay

Malay  हिन्दी

हिन्दी  Türkçe

Türkçe  العربية

العربية  Indonesia

Indonesia  تمل

تمل  український

український  فارسی

فارسی  Latine

Latine  Azərbaycan

Azərbaycan