How does the Roll Forming Machine empower metal processing across multiple key industries?

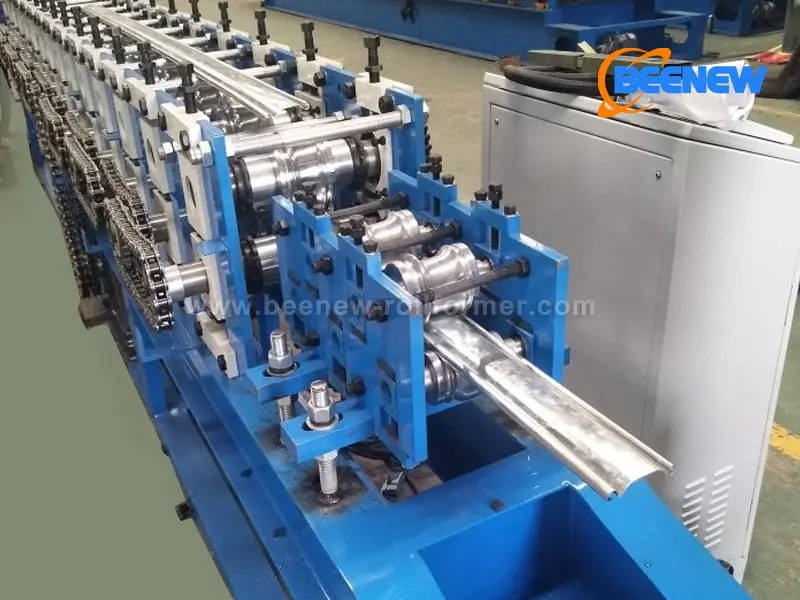

As the core equipment in the field of metal cold working, the Roll Forming Machine precisely processes metal sheets into various special-shaped profiles through a continuous progressive roll forming process. With its characteristics of "high efficiency in mass production, high precision, and low loss", it has deeply penetrated four major fields—construction and building materials, automotive manufacturing, home appliance production, and photovoltaic new energy—becoming a key equipment driving the large-scale and standardized production of the metal processing industry.

I. Construction & Building Materials Field: Mass-Produce Profiles, Lay a Solid Foundation for Infrastructure

The construction industry has a large demand for metal profiles with unified specifications, and the roll forming machine exhibits outstanding adaptability:

Processes construction materials such as C-section steel, Z-section steel, and color steel tiles; the daily output of a single production line reaches 5,000 meters, which is 3 times more efficient than traditional stamping processes;

Features forming precision of ±0.1mm and straightness error ≤ 0.5mm/m. Data from a steel structure workshop project shows that after using roll-formed profiles, the installation efficiency increased by 40%, and the material loss rate dropped from 8% to 1.2%.

II. Automotive Manufacturing Field: Customize Special-Shaped Components, Optimize Vehicle Performance

The automotive industry has an urgent demand for lightweight and high-precision components, and the roll forming machine provides customized solutions:

Processes special-shaped parts such as automotive door sills, roof crossbeams, and anti-collision beams; the forming qualification rate reaches 99.5% when processing high-strength steel;

Compared with welding processes, roll forming reduces component weight by 15% and improves body rigidity by 20%. Data from an automaker shows that after introducing the roll forming line, the production cycle of automotive chassis components was shortened by 30%.

III. Home Appliance Production Field: Precision-Process Casings, Enhance Product Texture

Home appliance casings and structural parts need to balance precision and aesthetics, and the roll forming machine meets refined requirements:

Processes components such as refrigerator door panels and air conditioner outdoor unit frames; the surface roughness Ra ≤ 0.8μm, eliminating the need for subsequent polishing and simplifying the production process by 50%;

Supports rapid model changeover for multiple specifications with mold change time ≤ 30 minutes, adapting to the multi-batch and small-batch production needs of the home appliance industry. An home appliance factory’s annual production capacity increased by 25% after adoption.

IV. Photovoltaic New Energy Field: Process Bracket Profiles, Adapt to Outdoor Scenarios

Photovoltaic brackets require high strength and weather resistance, and the roll forming machine ensures product stability:

Processes photovoltaic bracket guide rails and columns using aluminum alloy or galvanized steel; the compressive strength of formed profiles reaches 350MPa, and corrosion resistance is increased by 40%;

A single production line can be compatible with the processing of 4-8 types of bracket specifications. Data from a photovoltaic project shows that the installation error of roll-formed brackets is ≤ 2mm, significantly improving the laying efficiency of photovoltaic panels.

| Application Fields | Core Applications | Key Data | Compatible Materials |

|---|---|---|---|

| Construction & Building Materials | Processing of C-section steel, color steel tiles, etc. | Daily output 5,000 meters, loss rate 1.2% | Galvanized steel sheets, color-coated steel sheets |

| Automotive Manufacturing | Processing of automotive special-shaped structural parts | Qualification rate 99.5%, weight reduced by 15% | High-strength steel, aluminum alloy |

| Home Appliance Production | Processing of casings and structural parts | Mold change ≤ 30 minutes, Ra ≤ 0.8μm | Cold-rolled steel sheets, aluminum sheets |

| Photovoltaic New Energy | Processing of photovoltaic bracket profiles | Compressive strength 350MPa, error ≤ 2mm | Aluminum alloy, galvanized steel |

Currently, Roll Forming Machines are upgrading towards "intelligence and compounding": integrating PLC control systems to achieve automatic parameter adjustment, and adding compound functions such as punching and cutting to reduce process flow. As an "efficient tool" for metal forming, it will continue to empower large-scale production in multiple industries, helping the industry transform towards high precision and low energy consumption.

English

English lugha ya Kiswahili

lugha ya Kiswahili  Монгол хэл

Монгол хэл  Español

Español  Português

Português  русский

русский  Français

Français  日本語

日本語  Italiano

Italiano  한국어

한국어  Malay

Malay  हिन्दी

हिन्दी  Türkçe

Türkçe  العربية

العربية  Indonesia

Indonesia  تمل

تمل  український

український  فارسی

فارسی  Latine

Latine  Azərbaycan

Azərbaycan